About PILLER Blowers & Compressors

Future-oriented since 1909 - ALWAYS ADVANCING

Since its foundation in 1909, our company's development has been characterized by long-term plans and a forward-looking approach.

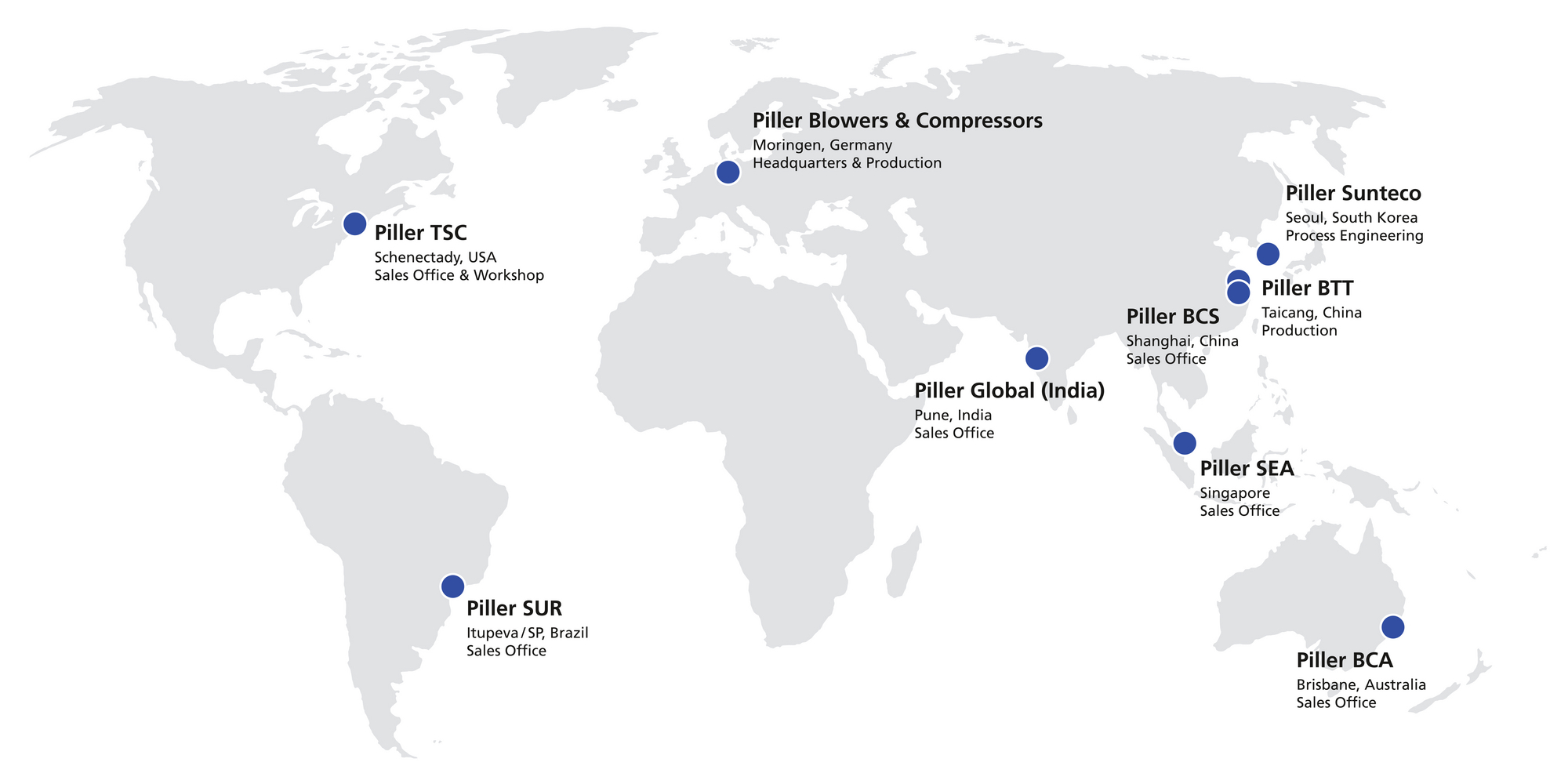

With over 500 employees worldwide and subsidiaries in the USA, Singapore, Australia and China as well as joint ventures in Korea, India and Brazil, we are now a medium-sized, family-owned company. As a global player, we export the majority of our machines.

What we do

At Piller Blowers & Compressors, we develop, design and manufacture compressors for the process industry. We supply efficient, economical and customized machines to meet our customers' requirements. They are used in the food industry, pulp and paper production, the chemical industry, the petrochemical industry, the pharmaceutical industry and in industrial wastewater treatment, among others.

A spirit of innovation

At PILLER, we combine a spirit of innovation and market-oriented research & development with comprehensive manufacturing expertise: we combine traditional manufacturing with our employees' high level of welding expertise with state-of-the-art machines and pioneering processes in industrial production.

The name PILLER stands for durable machines, maximum precision and compliance with all specified performance data. We meet our own high quality standards with comprehensive inspections and tests during production and reliably deliver top-quality products.

Sustainability at PILLER

The careful use of our world's finite resources is important to us.

That is why we take responsibility in this area.

Our compressors, which we have developed specifically for Mechanical Vapor Recompression (MVR) and vapor recovery processes, significantly increase energy efficiency in steam processes. Reductions in energy consumption of up to 75 percent have already been proven.

This results in CO2 savings of up to 60 percent in the processes and 90 percent energy cost savings for primary energy.

With our unique, innovative technology, we are therefore able to enable the transformation to resource-saving and sustainable production and at the same time ensure the performance of our customers.

Sustainability at the Moringen site

However, it is not only with our machines that we want to contribute to resource-conserving production; we are also taking the necessary steps ourselves on site.

In May 2023, for example, we put our PV system into operation at our main site in Moringen.

With the system, which covers a total area of 1329 m², we are reducing our dependence on energy supplies and our carbon footprint. At the same time, the plant allows us to absorb the maximum load peaks. We use between 90 and 95 percent of the electricity we produce ourselves and feed the rest into the grid.

Facts from our PV system

Annual production 2023

CO₂ savings in 2023

Self-sufficiency rate 2023

All about PILLER

We work together to realize our vision. We share fundamental values and the conviction that this is about more than maximizing profits.

Vision, Values & Purpose

Here you can find the most important key figures and information about PILLER at a glance.

Figures, Data & Facts

Our awards

Your contact to the HR department

Simone Heidelberg

Head of HR

05554 201-231

hr@piller.de

Adana Hartmann

HR generalist

5554 201-231

hr@piller.de

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271